Lockout Tagout Services

How well do you lockout/tagout?

Take a moment to assess the effectiveness of your lockout/tagout program, all aspects. Spend a day on the plant floor observing and talking to your operators. How much do you really know about your current program capabilities and overall needs of the team?

While you may be aware that the lockout/tagout program exists, understanding how well it works for your employees and what are the daily challenges can help identify opportunities for improvement. A road map for better safety awareness is to first understand what you have currently, then look at the challenges with the existing program, and finally understand resources and in-house limitations for program improvement.

Evaluating Your Current Lockout/Tagout Program:- At the equipment level, locate the current lockout/tagout procedure. Does a written procedure exist? Was the procedure easily accessible? Do operators know where to find it?

- If a current procedure exists, is it easy to follow? Do the instructions make sense? Could you identify all disconnects and valves that needed to be isolated? Was the procedure updated and accurate?

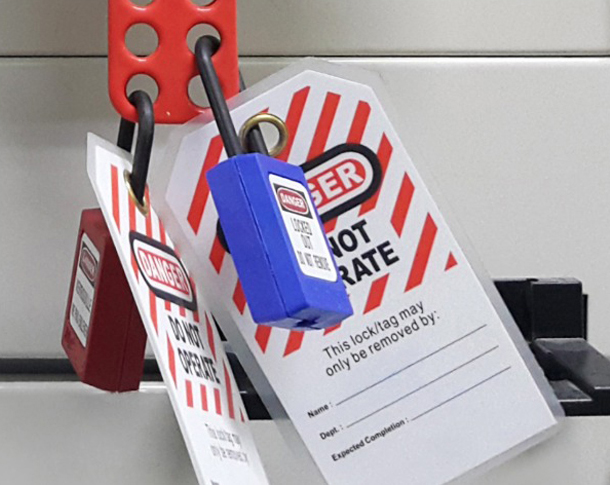

- Perform the current lockout/tagout procedure. Were the correct devices readily available? Could there be better options for location of devices? Would different devices be easier to use?

- Talk to employees about lockout/tagout. What questions do they have regarding the energy control program? What are their daily challenges?

Contact us to learn more.