Facility Storeroom Management (FSM)

HAVE YOU CONSIDERED THE COST OF UNPLANNED DOWNTIME?

We understand the unique challenges faced by large, complex operations in managing critical MRO inventory. These challenges often include:

- Limited Resources: Juggling competing priorities and budget constraints can hinder effective inventory management.

- Complex Purchasing Processes: Bureaucratic procedures and lengthy approval cycles can slow down critical repairs and increase downtime.

- Restricted Visibility: Lack of real-time data and accurate inventory tracking can lead to stockouts, excess inventory, and inefficient resource allocation.

- Inventory Expertise Gaps: Maintaining in-house expertise in MRO inventory management can be costly and challenging.

These obstacles can significantly impact operational efficiency, increase downtime, and hinder overall productivity.

Take Control of Your Storeroom:

- Dedicated resource(s) free your employee time to increase productivity

- Streamlined processes reduce your handling costs

- On-site expertise recommends stocking levels and driving product standardization

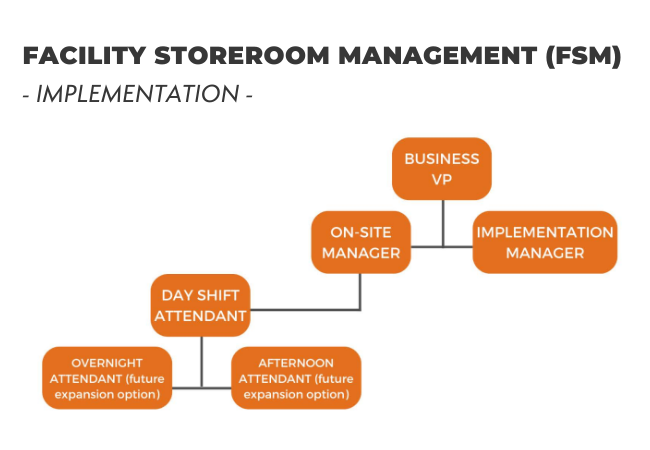

- Access to off-site inventory analysts that can provide guidance to you on setup within your ERP

TraxMRO's Facility Storeroom Management provides a dedicated, experienced resource on a daily basis to not only support your SMC product purchases, but also all purchases from other suppliers.

Contact us to learn more.