Save Time, Money & Headaches with a Unified Control Platform

We simplify industrial automation to help you succeed

Industrial operations are becoming increasingly complex.

Many organizations struggle with fragmented legacy systems, siloed data and unplanned downtime. While managers face rising cost pressures and productivity goals.

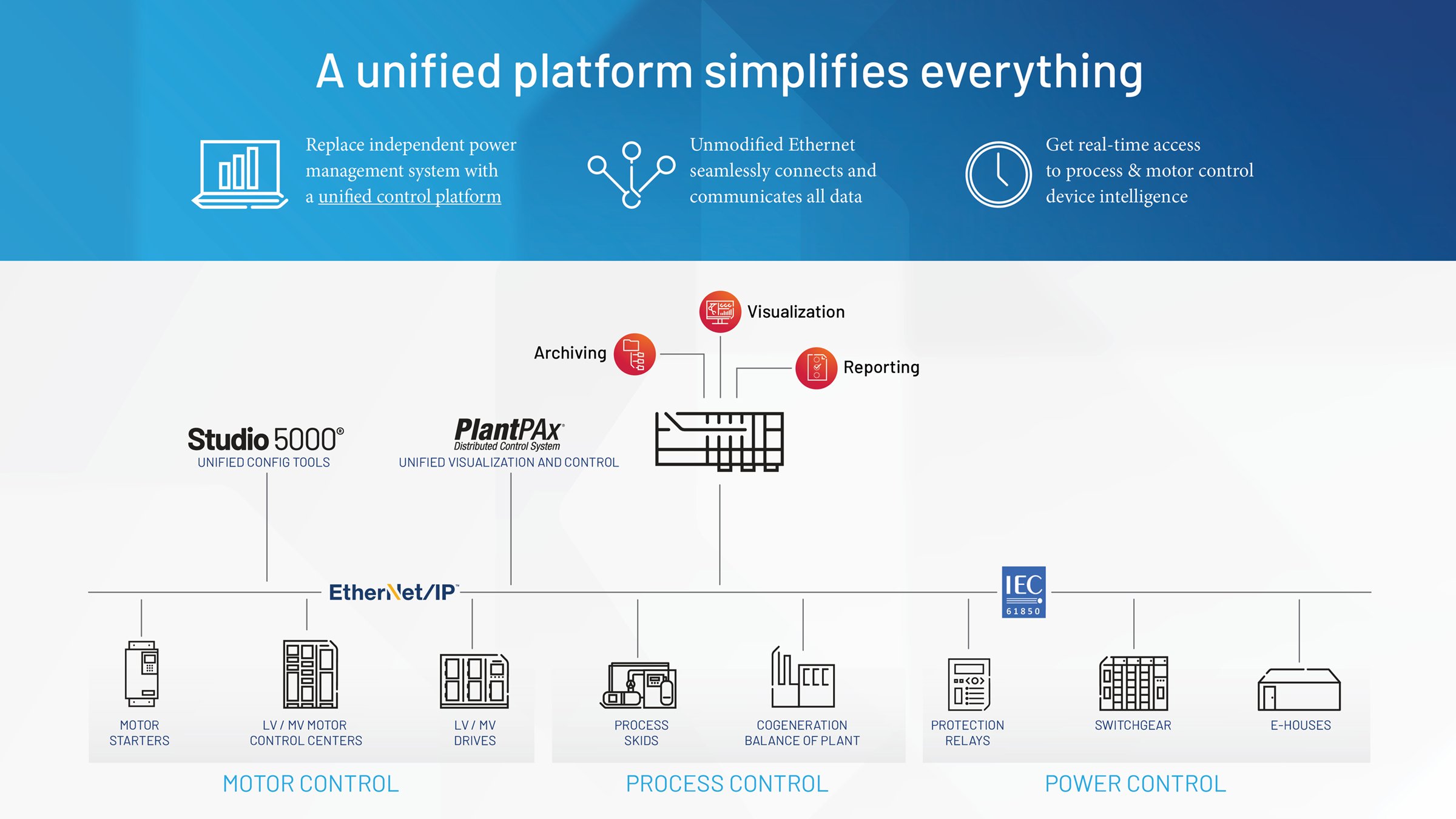

Rockwell Automation offers a unified solution that brings process and power control together under one architecture. Claudio Forte, a professional engineer and lead on the industry solutions team at Rockwell Automation says, “A single HMI offers visibility to real-time data originating from a unified process, power and control system.” He adds that it provides clear visibility into production and energy metrics on one platform, “That helps make your plant far more efficient, productive, predictable and profitable.”

The power of industrial automation

Increase your return on investment with a connected system. Instead of juggling multiple vendors, platforms and engineering environments, our unified process, power and motor control solution consolidates everything into one infrastructure and one version of the truth. This helps lower your design, hardware and total install costs:

- Reduce material, design, engineering, wiring and testing costs

- Faster installation, commissioning and time to market

- Reduce downtime with visibility to operating conditions, faults, predictive maintenance, alarms and events on one system

- Increase safety with 24/7 system monitoring from remote devices

An integrated system also reduces project complexity and risk. Plant engineers don’t need to design, learn, maintain and manage multiple systems, connections and interfaces.

This integrated smart portfolio can include:

- PlantPAx® DCS for plant-wide control with embedded cybersecurity and modular engineering

- CENTERLINE® motor control centers with IntelliCENTER® technology for safer, smarter motor control, and predictive maintenance

- Variable frequency drives (VFDs) for high-performance motor control and energy efficiency

- Programmable logic controllers (PLCs) to automate manufacturing processes, machinery and systems

- FactoryTalk® Analytics™ GuardianAI™ for predictive analytics and anomaly detection

- FactoryTalk® Suite for visualization, scalable analytics and centralized management

- Third-party device integration (OEM and instrumentation)

Together, these smart technologies deliver seamless integration, real-time intelligence and predictive analytics across your unified operation to help keep your plant running 24-7.

Unified control system benefits drive results

A unified architecture isn’t just about technology – it’s about transforming how you operate. Here’s what it can mean for your business:

- Faster deployment. Lower engineering effort and expense: Pre-tested, validated designs and a single engineering environment help cut integration time by up to 80% and accelerate installation by up to 25%

- Smarter decisions & better operator experience: Standardized control tools and graphics on one dashboard give operators real-time insights into equipment health, energy use and process conditions – reducing training time and improving responsiveness

- Reliability, safety & always-on performance: Centralized alarming, integrated safety and predictive maintenance reduce downtime to help keep operations running

- One source of truth for data: No more reviewing multiple dashboards. Our unified system synchronizes and time stamps data across process and power control

Planning a plant expansion? Get support from the industry leader

Manufacturers get countless advantages from a unified system. You can connect process, power and motor control on one platform. Plus, get real-time operational data, predictive analytics, energy management and more... making your plant more efficient and profitable. In addition:

- Our unified solution helps deliver significant savings on both total install costs and your total cost of ownership for the lifetime of the system

- You can get support from Rockwell Automation consultants at every necessary stage. Our teams have decades of experience designing, commissioning and supporting industrial solutions

- Simplify your plant production complexity and reduce project risk by engaging with our team and PartnerNetwork™ that works together regularly

- We work with engineering, procurement and construction teams, and system integrators

Contact an expert to help with your industrial automation journey.